Liposome & Lipid Nanoparticle Preparation and Production Equipment

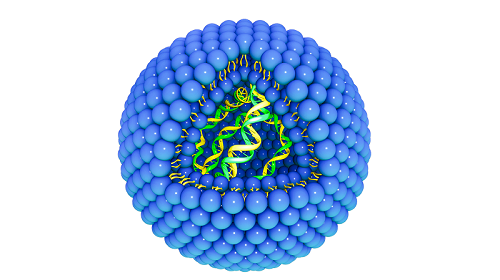

Liposomes are artificially synthesized vesicles composed of phospholipids and cholesterol that mimic biological cell membranes. Their particle sizes typically range from 50–200 nm and can be adjusted according to preparation methods. Liposomes can encapsulate both hydrophilic and hydrophobic compounds and are widely studied for drug delivery, gene delivery, and vaccine formulation research.

In pharmaceutical research, lipid nanoparticles (LNPs) represent a broader class of lipid-based delivery systems, within which liposomes are a well-established and extensively characterized subclass. Precise control of particle size and distribution is critical in both liposome preparation and lipid nanoparticle production, as these parameters directly influence formulation stability, reproducibility, and in vivo performance.

As liposome- and LNP-based formulations continue to expand in clinical and commercial applications, they are often categorized as complex injectable dosage forms. Their development requires dedicated processing equipment and carefully controlled production parameters. Among these parameters, particle size control remains one of the most critical factors for ensuring batch-to-batch consistency and predictable delivery behavior.

Common techniques for reducing liposome and lipid nanoparticle size include ultrasonication, shearing, high-pressure homogenization (HPH), and membrane extrusion. Genizer focuses on shearing, extrusion, and HPH-based technologies, supporting scalable preparation from laboratory research through pilot and industrial production.

Particle Size Reduction Technologies

1. Shearing

Shearing applies mechanical forces as samples pass through narrow gaps at high rotational speeds, resulting in particle size refinement. Excessive energy may disrupt lipid bilayer structures, so shearing is typically used as a pretreatment step or for specific formulations such as multilamellar vesicles or passively loaded liposomes.

2. High-Pressure Homogenization (HPH)

High-pressure homogenization is a widely adopted method for producing liposomes and lipid nanoparticles with controlled particle size. As formulations pass through high-pressure interaction chambers, they are subjected to shear, impact, and turbulence, resulting in efficient size reduction while maintaining formulation consistency across different processing scales.

3. Extrusion

Liposome Extrusion Mechanism

Extrusion involves forcing lipid vesicles through membranes at temperatures above the phospholipid phase transition point. Particle size is governed by membrane pore size, applied pressure, and processing temperature. Proper optimization enables narrow particle size distributions and high reproducibility, making extrusion particularly suitable for applications requiring uniform liposome populations.

Liposome Extrusion Size Distribution

Genizer Liposome and Lipid Nanoparticle Equipment

- Hand Driven Liposome Extruder: Designed for small-scale laboratory preparation with processing volumes from 0.1–2.5 mL

- Pneumatic Liposome Extrusion System: Suitable for medium-scale and continuous operation, supporting volumes from 10 mL to 10 L

- High-Pressure Sanitary Pump with Online Liposome Extrusion System: Scalable from laboratory to industrial production, enabling controlled particle sizes in the range of 80–250 nm and supporting higher throughput via modular configurations

- High-Pressure Homogenizer (HPH): Available for laboratory-scale applications (NanoGenizer) and large-scale manufacturing (WILL Series)

Additional Advantages

- Scalable configurations supporting continuous processing from research to production

- Temperature control options, including pre-heating and rapid post-process cooling, to support particle size stability

These systems can be configured individually or in combination according to specific formulation and production requirements, enabling efficient and reproducible liposome and lipid nanoparticle preparation.

Applications of Liposomes and Lipid Nanoparticles

Liposome- and LNP-based formulations are commonly applied in:

- Targeted drug delivery to improve circulation time and formulation stability

- Vaccine delivery systems and adjuvant research

- Anticancer, anti-infective, and immunotherapy development

By adjusting particle size, polydispersity, and processing parameters, uniform and stable lipid-based nanoparticles can be obtained with improved encapsulation performance and formulation robustness.

Explore Genizer Liposome Equipment

Select the appropriate system for your laboratory or production requirements:

Comments

Post a Comment